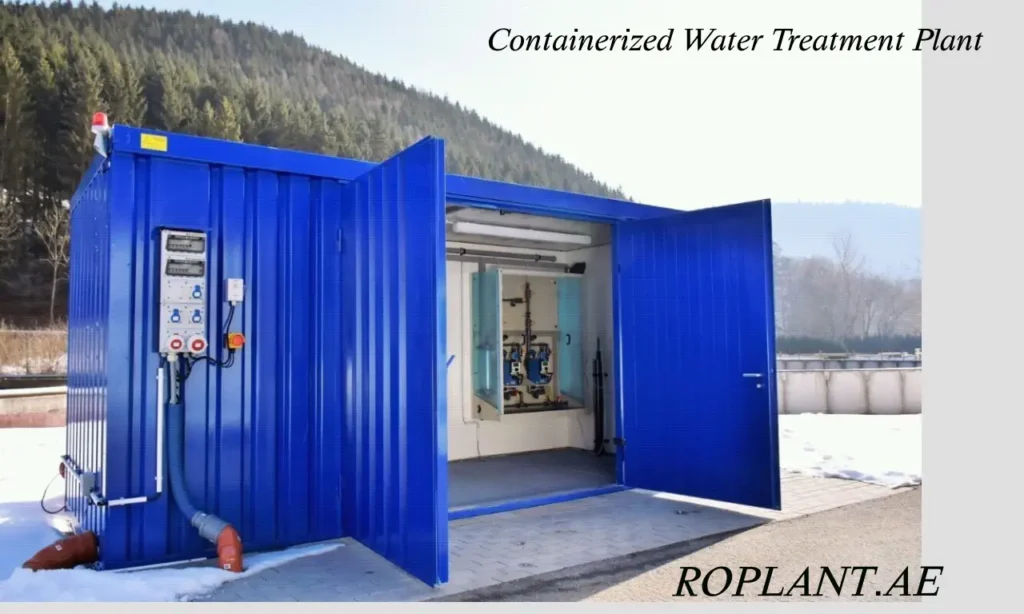

Containerized Reverse Osmosis System (CRO) is an innovative and efficient RO Plant water treatment company uae solution that has gained significant popularity in various industries. This article explores the concept of containerized reverse osmosis systems. Their benefits, applications, working principles, key components, factors to consider when choosing a system, maintenance requirements, cost considerations, future trends, and more.

Introduction

Water scarcity and the need for reliable water treatment companies in UAE solutions have led to the development of containerized reverse osmosis system. These systems offer a compact, portable solution for producing high-quality purified water in diverse environments. For industrial processes, remote locations, disaster relief efforts, or temporary water treatment needs, containerized reverse osmosis systems provide a versatile and efficient approach.

What is a Containerized Reverse Osmosis System?

A containerized reverse osmosis system is a self-contained unit that integrates all the necessary components for water purification into a single shipping container. It typically includes pre-treatment filters, high-pressure pumps, reverse osmosis membranes, chemical dosing systems, instrumentation, and control systems. The method is created to be easily enchanted, installed, and operated, offering flexibility and convenience for various applications.

Benefits of Containerized Reverse Osmosis Systems

Containerized reverse osmosis system offer several advantages over traditional water treatment systems. These benefits include:

- Portability: The modular design of containerized systems allows for easy transportation and rapid deployment in different locations.

- Space Efficiency: These systems optimize space utilization and minimize footprint requirements by housing all the components within a single container.

- Quick Installation: Containerized systems are designed for fast setup and commissioning, reducing the time required to start water treatment operations.

- Flexibility: These systems can be customized to meet specific water quality and capacity requirements, making them adaptable to various applications.

- Scalability: Containerized systems can be easily expanded or downsized based on changing water demands, providing scalability and cost-effectiveness.

- Reduced Environmental Impact: The compact design and efficient operation of containerized systems contribute to lower energy consumption and carbon emissions.

Applications of Containerized Reverse Osmosis Systems

Containerized reverse osmosis system by RO plant find applications in diverse industries and settings. Some common applications include:

Industrial Processes

Containerized reverse osmosis systems are extensively used in manufacturing, power generation, food and beverage, pharmaceuticals, and oil and gas. They provide a reliable source of purified water for production processes, boiler feed water, cooling tower makeup, and other industrial applications.

Remote Locations

In small areas with unreasonable entry to cleanse water, containerized reverse osmosis systems offer an efficient solution. These systems can be deployed in mining camps, construction sites, military bases. The off-grid communities to provide safe drinking water and support essential operations.

Disaster Relief

During natural disasters or emergencies, containerized reverse osmosis systems play a crucial role in providing immediate access to clean water. They can be rapidly deployed to disaster-stricken areas, ensuring a stable supply of safe drinking water for affected populations.

Temporary Water Treatment

Containerized systems are also utilized for temporary water treatment needs during events, festivals, or construction projects. They present a opportunely and cost-effective resolution for keeping water grade and meeting the quick demand.

How Does a Containerized Reverse Osmosis System Work?

Containerized reverse osmosis systems employ the principle of reverse osmosis to remove contaminants and impurities from water. The process involves the following steps:

- Pre-Treatment: The incoming water passes through various pre-treatment filters to remove suspended solids, sediment, chlorine, and other impurities that could damage the reverse osmosis membranes.

- High-Pressure Pumping: The pre-treated water is pressurized using high-pressure pumps to overcome the osmotic pressure and force it through the reverse osmosis membranes.

- Reverse Osmosis: The pressurized water is forced through the semi-permeable membranes, where the smaller water molecules pass through while larger contaminants are rejected and flushed away.

- Product Water Storage: The purified water, known as product water or permeate, is collected and stored in a dedicated tank within the container.

- Brine Disposal: The concentrated brine containing the rejected contaminants is discharged or recycled appropriately, depending on the application and local regulations.

- Chemical Dosing and Monitoring: Containerized systems often include chemical dosing systems to ensure optimal performance and prevent membrane fouling. Instrumentation and control systems monitor the water quality and system parameters for efficient operation.

Advantages of Containerized Reverse Osmosis Systems

Containerized reverse osmosis systems offer numerous advantages, making them a preferred choice for many water treatment applications. These advantages include:

- Rapid Deployment: Containerized systems can be quickly transported and set up, reducing the time required to establish water treatment operations.

- Cost-Effectiveness: The modular design and scalability of containerized systems allow for cost optimization by matching the water treatment capacity to the specific requirements.

- Ease of Operation: These systems are designed for ease of use and require minimal operator training. The integrated control systems simplify operations and enable remote monitoring and control.

- Reliability: Containerized systems incorporate robust components and undergo rigorous testing to ensure they deliver reliable and consistent performance in challenging environments.

- Mobility: Containerized systems’ portability allows users to relocate them effortlessly to different sites as needed, making them ideal for temporary or mobile water treatment applications.

Key Components of a Containerized Reverse Osmosis System

Containerized reverse osmosis system comprise various components, each vital in the water treatment. The key components include:

- Pre-Treatment Filters: These filters remove sediments, suspended solids, chlorine, and other impurities to protect the reverse osmosis membranes.

- High-Pressure Pumps: The pumps create the required force to crush the osmotic tension and move the water via the membranes.

- Reverse Osmosis Membranes: These semi-permeable membranes remove dissolved solids, salts, and other contaminants, producing purified water.

- Chemical Dosing Systems: Chemical dosing systems prevent membrane fouling and optimize system performance by adding anti-scalants and disinfectants.

- Instrumentation and Control Systems: These systems monitor and control parameters such as pressure, flow rates, water quality, and system performance, ensuring efficient operation and early detection of any issues.

Factors to Consider When Choosing a Containerized Reverse Osmosis System

When you choose a containerized reverse osmosis system, you need to consider several factors to ensure. That the system meets the specific requirements of your application. These factors include:

- Water Quality: You should assess the quality of the source water and identify the contaminants that you need to remove or reduce.

- Water Demand: Determine the required water treatment capacity to meet the demand, considering current and future needs.

- Space Limitations: Evaluate the available space for system installation and choose a container size and configuration that fits the designated area.

- Power Supply: Consider the availability of power sources and select a system that aligns with the available power infrastructure or incorporates alternative power options.

- Mobility Requirements: If you require frequent relocation of the system, opt for a containerized system that offers easy transportation and setup..

- Maintenance and Service: Assess the maintenance requirements and availability of technical support from the system provider, ensuring smooth operation and timely service.

Maintenance and Troubleshooting of Containerized Reverse Osmosis Systems

Regular maintenance and troubleshooting are essential to maintain the performance and longevity of a containerized reverse osmosis system. Some key maintenance tasks include:

- Preventive Maintenance: Perform routine checks, filter replacements, and system inspections according to the manufacturer’s guidelines.

- Membrane Cleaning: Periodically clean the reverse osmosis membranes to remove any accumulated fouling substances and ensure optimal performance.

- Chemical Dosing: Regularly monitor and adjust chemical dosing to prevent scaling, biological growth, and membrane fouling.

- System Monitoring: Continuously monitor system parameters, such as pressure, flow rates, and water quality, to identify deviations or abnormalities.

- Troubleshooting: Develop a troubleshooting procedure to diagnose and resolve common issues, such as low product water quality, low pressure, or system malfunctions.

Cost Considerations for Containerized Reverse Osmosis Systems

The cost of a containerized reverse osmosis system depends on various factors, including system capacity. The customization requirements, quality of components, and additional features. You should evaluate the complete cost of the request, considering not only the initial investment cost. But also the facility, operation, maintenance, and potential system upgrades. It is crucial to compare different system providers, evaluate their track records. The ensure the system offers the best value for the specific application.

Future Trends and Innovations in Containerized Reverse Osmosis Systems

Containerized reverse osmosis systems continue to evolve with technological advancements and growing water treatment needs. Some considerable forthcoming trends and inventions retain:

- Energy Efficiency: Further advancements in energy recovery devices and improved membrane materials aim to enhance the overall energy efficiency of containerized systems.

- Smart Monitoring and Control: Integration of advanced monitoring and control systems, IoT (Internet of Things) capabilities, and data analytics will enable remote monitoring, predictive maintenance, and system optimization.

- Membrane Technology: Ongoing research and development in membrane materials and design aims to enhance performance, reduce fouling, and extend the lifespan of reverse osmosis membranes.

- Water Reuse and Resource Recovery: Containerized systems may incorporate additional water reuse and resource recovery treatment processes, contributing to sustainability and circular economy initiatives.

Successful Containerized Reverse Osmosis System Implementations

Several real-world examples highlight the successful implementation of containerized reverse osmosis systems in different industries and locations. These case studies demonstrate these systems’ versatility, efficiency, and effectiveness in meeting diverse water treatment needs. Here are a few examples:

- Industrial Water Treatment: A manufacturing plant in a water-stressed region installed a containerized reverse osmosis system to meet their process water demands. The system provided reliable, high-quality water, reducing reliance on external water sources and ensuring uninterrupted production.

- Remote Mining Camp: A mining company operating in a remote location implemented a containerized reverse osmosis system to supply clean drinking water to their workers. The mobility of the system enabled easy relocation as the mining operations progressed.

- Disaster Relief: Following a natural disaster, a containerized reverse osmosis system was deployed to supply safe drinking water to impacted residents. The system rapidly designated a regular water collection, helping relief efforts and reducing the dependency on bottled water shipments.

These case studies highlight the effectiveness and versatility of containerized reverse osmosis systems in various contexts. From addressing unique water treatment challenges and ensuring access to clean water.

Environmental Impact of Containerized Reverse Osmosis Systems

Containerized reverse osmosis systems offer several environmental benefits compared to conventional water treatment methods. These include:

- Water Conservation: By efficiently removing contaminants and purifying water system. These systems contribute to water conservation efforts, reducing the strain on freshwater resources.

- Energy Efficiency: Containerized systems incorporate energy recovery devices and advanced control systems, optimizing energy consumption and minimizing carbon emissions.

- Reduced Chemical Usage: Using reverse osmosis membranes reduces the need for chemical additives typically used in traditional water treatment company uae processes. Minimizing the overall chemical footprint.

- Waste Reduction: Containerized systems generate less waste compared to conventional treatment methods. To manage the brine discharge appropriately, it is essential to consider environmental regulations and potential opportunities for reuse.

By considering the environmental impact and implementing sustainable practices, containerized reverse osmosis systems. Contribute to a greener and more efficient water treatment landscape.